Test infrastructure

Electrification, automated driving and new forms of energy also pose enormous challenges for the test infrastructure. The availability of capacities and the know-how required to implement industry-compliant tests is ensured across the board in the network. On top of this, leading players from industry and research are cooperating to continuously expand these offerings.

Best Practices

TIZ Grieskirchen

Whether machines, materials or vehicles – the Test Institute TIZ Grieskirchen offers a comprehensive range of services in the field of measuring and testing technology. The key domain of the test procedures is testing individual assemblies and complete machines under dynamic loads.

>> more information (german)

Zero Defect Manufacturing

A “zero defect manufacturing” solution for thermodynamic processes is being developed, based on widespread production processes, such as curing carbon fibre composite components in autoclaves, etc. This includes converting the raw data using data-driven predictive models and physical simulation models, and developing AI methods to model the relationships between the process parameters, product data, and quality characteristics.

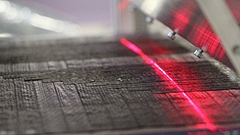

Zero-contact and non-destructive testing/analysis using laser ultrasound, terahertz technology, OCT measurement technology

The implementation of welds in the automotive sector is one example of a safety-relevant process that requires precise control. Laser ultrasound makes it possible to inspect welds during the production process. Generally speaking, various process-integrated, zero-contact and non-destructive measurement and analysis methods allow for early detection of potential defects. This saves time, energy and costs, while ensuring the quality of the products.

>> more information (german)

Adaptive Smart Production 2 Project (Production Systems of the Future meet Mobility of the Future)

In collaboration between partners AVL and the Institutes of Production Engineering and Machine Components (both Graz University of Technology), the project is looking into the assembly processes for fuel cell-powered drivetrain solutions and the associated storage systems. With regard to the first of these topics, the focus is on the agility of assembly processes for both battery- and fuel cell-powered powertrains. The second focus topic investigates the suitability of warehouses and warehousing systems for innovative powertrains.

WS2CARE - Cyber Security for Vehicles of the Future (Replacing Wire with Wireless)

The project aims to develop a test framework based on security standards that will identify, verify, and validate wireless components in vehicles to facilitate cybersecurity testing, and provide input for new safeguards. The test tool relies on a hierarchical test structure, ranging from the most critical vulnerabilities to the less important ones.