Energy storage and electric drivetrains

The key fields of expertise in novel vehicle solutions centre on the trend towards electric drivetrains, requiring new expertise, and with a need to ideally complement the appropriate energy storage systems. Electric machines, transmissions, batteries and fuel cells are the essential components that generate value.

Best Practices

maxE

The maxE project seeks to reduce greenhouse gas, noise and particulate matter emissions at construction sites, avoid the negative impact on the power grid, and promote the use of renewable electricity at construction sites. The aim is to use a battery storage system to achieve this.

>> more information (german)

Bio!Lib

The project centres around the development of a lightweight battery tray made of a steel-wood laminate composite, where the wood complements the properties of steel. The benefits lie in strength and fire protection, crash behaviour, the environmental footprint and recycling. The project partners are FILL, nolax, Weitzer, TU Graz, Boku, W.E.I.Z. and the Automobil-Cluster (Automotive Cluster).

>> more information (german)

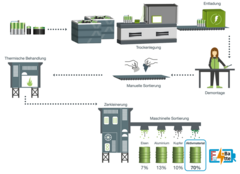

FuLiBatteR - Recycling of lithium-ion batteries

K1-MET is all about closing material cycles with a focus on recovering critical raw materials from the active material of lithium-ion batteries from different fields of application (automotive, stationary and portable storage media). FuLiBatteR reduces the dependence on global raw material markets and aims to combine the disciplines of waste management, process engineering, metallurgy and biotechnology to recover lithium-ion batteries without leaving fractions which need to be landfilled.

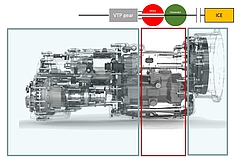

Emission-reducing CVT transmission with an electrical variator for commercial vehicles

The replacement of a hydrostatic power unit from an existing transmission (mainly used in agriculture) with an electric machine will be investigated in the scope of the project. To further boost the efficiency of what will be an electric eCVT unit from this point onwards, innovative and cost-efficient electrical components will be installed for the alternator (to power a battery installed in the vehicle) and the electric-motor and alternator units.

>> more information (AIT)

>> more information (LCM)